What is a truck mounted crane

Truck-mounted crane is a kind of equipment that realizes the lifting, turning and hoisting of goods by hydraulic lifting and telescopic system. It is usually assembled on trucks and integrates hoisting and transportation. used in the station, warehouse, port, construction side and field rescue. It can be equipped with different lengths of cargo boxes and different tonnages cranes. According to the tonnage, it can be divided into 2 tons, 3.2 tons, 4 tons, 5 tons, 6.3 tons, 8 tons, 10 tons, 12 tons, 16 tons and 20 tons.

It is generally composed of truck chassis, cargo compartment and a crane.

According to the type of crane, it is divided into telescopic type straight arm type and folding arm type.

Fordable crane

Advantages: good mobility, rapid transfer, can integrate hoisting and transportation functions, improve resource utilization, and can load various grabbing tools, such as wood grabs, hanging baskets, brick clamps, drilling tools, etc., to achieve Multi-application work.

Disadvantages: It is not suitable for working on large slopes, soft or muddy sites, and its hoisting performance is stronger then truck cranes.

What is a truck crane

The truck crane is a kind of crane installed on the ordinary truck chassis or the special truck chassis, and its driving cab is set separately from the lifting control room. The advantage of this kind of crane is good maneuverability and quick transfer. The disadvantage is that it cannot be driven under load, and it is not suitable for working on soft or muddy fields. Can only hoisting, not transportation. But the lifting tonnage is much larger than the truck-mounted crane. The smallest is more than 20 tons, and the largest can reach 500 tons.

The three most important parts of the truck mounted crane

The truck-mounted crane is mainly composed of three parts: the chassis, the crane, and the cargo box.

Chassis

The chassis is very important, whether the vehicle is solid or not depends on the chassis

- The engine on the chassis of the truck-mounted crane is the source of all power, which not only affects the lifting capacity and speed of the crane, but also affects the load.

- The chassis used by the truck-mounted crane is a special chassis, which is mainly reflected in the girder. The chassis girder of the truck-mounted crane is thicker than the general cargo chassis girder. For example, 8-ton truck-mounted crane, the general cargo chassis girder is generally double-layered, the thickness is 250mm, but the chassis girder of the truck-mounted crane is generally partial three-layer or entire three-layer, the thickness is 300mm;

- The front and rear axles of the chassis directly affect the load-bearing capacity of the whole vehicle. The front and rear axles of the special chassis for truck-mounted cranes are larger than the general cargo chassis. For example, Dongfeng rear double axles, the general cargo chassis is assembled with 153 rear axles, but for the truck-mounted cranes, it is assembled Dongfeng Dana axle, which is generally 11.5 tons and 13 tons,

In short, the girders of the special chassis for truck cranes are stronger and thicker than the chassis of ordinary trucks, and they are basically three-layer thickened girders. The load-bearing capacity and tensile strength of the whole vehicle are stronger, and the performance of the truck-mounted crane can be better played. The special chassis of the truck-mounted crane has a special gearbox and pre-installed with a special power take-off. No need to modify the air circuit and wire circuit anymore. The installation and distribution positions of the air tank, battery and exhaust pipe are more suitable for crane installation. Improper operations such as welding and cutting of the chassis are avoided.

Chassis brands in the domestic market, such as Jiefang J6P, Dongfeng Tianlong, Liuqi Chenglong H5, Shaanxi Automobile Delong M3000, etc., are all dedicated chassis for high-end truck-mounted cranes.

crane

The crane is the core, whether the attendance rate is high depends on the crane

The quality of the crane directly affects the lifting capacity. The most important part of the crane is the boom and hydraulic system. The material of the boom is the core of the bearing capacity. If the material is not good, the boom is easy to deform. For example, XCMG crane, It is made of manganese steel, with a hexagonal arm body, which has a compromise ability and strong bending resistance;

The operation speed of the crane is also very important. The operation speed depends on the overall performance of the hydraulic system and the oil supply. The larger the oil supply, the smoother the lifting and the faster the speed. For example, XCMG 12 ton crane, the hydraulic system flow of the combined pump is 100L/min, and the hydraulic system flow of the single pump is 63L/min.

At present, the first-line crane brands are: XCMG, Sany, Shimei, Hongchang Tianma, etc. In fact, XCMG and Sany should have the best sales and the most stable quality. In terms of price, Sany is more expensive than XCMG.

Cranes are divided into telescopic straight arm cranes and folding arm cranes. Relatively speaking, straight arm truck cranes occupy the main market. Straight arm truck mounted crane is easy to use and affordable, with a minimum tonnage of 2 tons and a maximum tonnage of 20 tons. Folding arm truck crane, flexible operation and high efficiency, the minimum tonnage is 1.5 tons, and the maximum tonnage is 30 tons.

Advantages of straight arm truck crane

The straight arm truck mounted crane occupies 70% of the market, with large sales volume and stable product performance. The straight arm crane has simple structure, convenient operation, mature technology, easy purchase of accessories, low maintenance cost and affordable price.

Advantages of folding arm truck crane

Folding arm truck crane, in the far sea area, prefer the folding arm crane. The folding arm crane has higher working efficiency, more accurate work, can cope with various working environments, is more flexible and has strong lifting capacity.

What are the tonnages of the straight arm truck-mounted crane?

For example, XCMG truck-mounted cranes, the crane tonnages currently sold by XCMG include: 2 tons, 3.2 tons, 5 tons, 6.3 tons, 8 tons, 10 tons, 12 tons, 14 tons, 16 tons, and 20 tons, the sales volume of 8 ton, 10 ton cranes is the largest. Other crane brands such as Sany, Shimei, Hongchang Tianma and Chengli cranes have basically the same tonnage as XCMG cranes.

Practical first, quality before price! Choosing a crane is mainly to choose tonnage. The crane tonnage should be selected according to the needs of working conditions (transportation priority or lifting priority), and according to the rigid constraints of the chassis (the output capacity of the power take-off, the weight of the chassis, etc.). The tonnage of the crane is too small, the efficiency is low, and the work force is not enough; if it is too large, it may be limited by the output capacity of the power take-off and cannot give full play to the performance of the crane, and it may also damage the chassis power take-off, girder and other assemblies, and may cause overturning accidents in serious cases.

Cargo box

The cargo box is the key, and the safety of the cargo depends on the cargo box

The cargo box is one of the important components of the truck-mounted crane. A high-quality truck-mounted crane must have a good-quality cargo box. The strength and length of the cargo box are related to the performance of the vehicle. Don’t think that the carriage is a small head, there is not much difference between good and bad. In fact, in terms of price, the average price of a 8.5M carriage is only about $1600 and a cargo box with high strength and good bearing capacity needs $2800, and the price difference is $1200. Let’s popularize the knowledge of cargo box to help you:

Firstly, the size of the chassis determines the length of the truck-mounted cargo box

4×2 model, wheelbase 4500mm, cargo box length 5100mm;

6×4 model, wheelbase 5000+1350mm, cargo box length 6200mm; wheelbase 5900+1350mm, cargo box length 8.3 meters;

8×4 models, the length of the cargo box is 8.3 meters to 8.5 meters.

Secondly, entire auxiliary beam – the standard configuration of high-strength cargo box

If you want to customize the high-strength cargo box, thicken the box plate, encrypt the beam, and install the entire auxiliary beam, these configurations must be installed. Entire auxiliary beam can improve the strength and loading capacity of chassis obviously, so it was recommended strongly by truck crane manufacturers. For single-axle models, the price of installing the entire auxiliary beam is $480, and for the 6×4 and 8×4 model, the installation of the auxiliary beam is $640.

Thirdly, the appearance of the thickness of the truck-mounted cargo box

The truck-mounted cargo box is divided into striped type and flat type, nowadays most of the striped cargo boxes are used in the market. The thickness of the ordinary cargo box is generally sides 2mm and bottoms 4mm, the fence plate of the cargo box is 2mm thick, and the bottom plate is 4mm thick. The chassis can choose a antiskid plate or a flat plate. Under normal circumstances, it is common to recommend that users choose a cargo box with 3mm sides and 5mm bottoms. This kind of cargo box has high strength, strong loading capacity, and is not easy to deform after long-term use.

The difference between a good cargobox and a bad cargobox

- The thickness of the box plate, the high-quality carriage adopts 3mm sides and 5mm bottoms, and the inferior carriage adopts 1.5 sides and 3mm bottom, and the thickness of the box plate is almost 1 and a half;

- For the entire auxiliary beam, the good carriages will be equipped with the auxiliary beam structure, and the poor carriages use two disconnected auxiliary beams;

- Beam side beams, good cargobox are made of 10×10 thickened rolled steel, while inferior cargo boxes are made of 5×10 channel steel;

- The production process, the good cargo box adopts the assembly line operation, the quality is no difference, the inferior cargo box, the craftsmanship of masters is different, the quality is different.

In short,

The working environment of the truck-mounted crane is generally poor. It is mostly used on the construction site, loaded with steel bars, and has a lot of equipment. This kind of use is definitely need a good cargo box, and the inside of the compartment door should be as smooth as possible, etc. When loading steel pipes, steel bars, hoisting, and hanging door panels, you will know the benefits of the smooth inner wall of the door panel.

Matching relationship between chassis, crane and cargo box

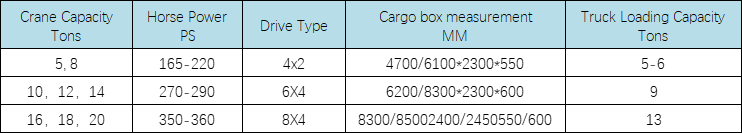

For different chassis sizes, it is necessary to select a crane with a suitable tonnage according to the chassis structure, wheelbase, engine and other factors, which can not only ensure that the vehicle is not overweight, but also ensure that the performance of the vehicle crane can be fully utilized.

The combination of the chassis of the truck mounted crane and the crane described above fully takes into account the vehicle performance, as well as the vehicle size, weight and other factors, which can not only ensure that users can go through the registration procedures normally, but also ensure that the chassis performance and crane performance are sufficient. play.